By Lauren Nagel

Popular belief holds that, at least in theory, single-blade propellers achieve a higher efficiency than same size propellers with more blades. This phenomenon has a few different explanations, which we will dive into below.

We decided to put the theory to the test, comparing the performance of a single-blade drone propeller with a two-blade propeller of the same make.

Read on to see our unexpected results.

Table of contents:

-

Why Are Single-Blade Propellers More Efficient

-

Experimental Setup

-

Results: 1-Blade vs. 2-Blade Propellers

- RPM and Thrust

- Propeller Efficiency

-

Overall Efficiency

-

Discussion: Performance Trade-offs and Confounding Factors

1. Why Are Single-Blade Propellers More Efficient

Single-blade propellers have been used commercially in a handful of cases, including modified Piper Cubs and motorized gliders, but have not otherwise gained much traction.

This is somewhat surprising considering that 1-blade models are supposedly more efficient than models with 2+ blades, so why aren’t they more common?

Let’s start by looking at the theory behind single-blade propellers’ enhanced efficiency.

One theory proposes that fewer blades means fewer sources of energy-sapping blade tip vortices. These vortices can result in energy loss at low advance ratios, so limiting them can improve efficiency.

Another leading theory states that single-blade propellers are more efficient because they don’t experience the wake turbulence of other blades, and thus rotate through less disturbed air.

To find out if this theory holds true in practice, we put it to the test using our Flight Stand 15.

Figure 1: testing single and two-blade propellers of the same size and make

2. Experimental Setup

For this experiment, we acquired a set of carbon fiber propellers and modified one of the two into a single-blade propeller. We then performed a simple step test across a range of RPMs.

Creating the single-blade propeller

The process to create the single-blade propeller was fairly simple:

-

Cut off the majority of one of the blades

-

Drill a hole in the center of the remainder of the blade

-

Secure a bolt in the hole

Figure 2: Close-up of the single-blade propeller after modifications

-

Roughly balance the propeller using a static balancer, adjusting the bolt and/ or add washers until it is visibly balanced

Figure 3: single-blade propeller mounted on a static balancer

-

Dynamically balance the propeller using the Flight Stand, adding tape to obtain an acceptable ISO quality grade (6.996 G)

Figure 4: Balancing the single-blade propeller with the Flight Stand software

While we were aiming to achieve a quality grade of 6.3 G, it was not possible despite several attempts and increasingly precise weight corrections (discussion in section 4).

The Flight Stand 15 measures vibration to evaluate the quality of the balancing in the system, so it could be that the aerodynamic effects of the bolt influenced the results, that the axial position of the counter weight requires two plane balancing, or that the unbalanced thrust is simply causing more noise...

The two-blade propeller achieved a quality grade of 5.552 G without any modifications.

The single-blade propeller had a final mass of 29 g, while the two-blade propeller had a mass of 18 g.

We used one clockwise (CW) and one counterclockwise (CCW) propeller, as these were what we had on hand, and this difference is not expected to impact performance.

Figure 5: modified single and two-blade propellers side by side

Performance comparison test

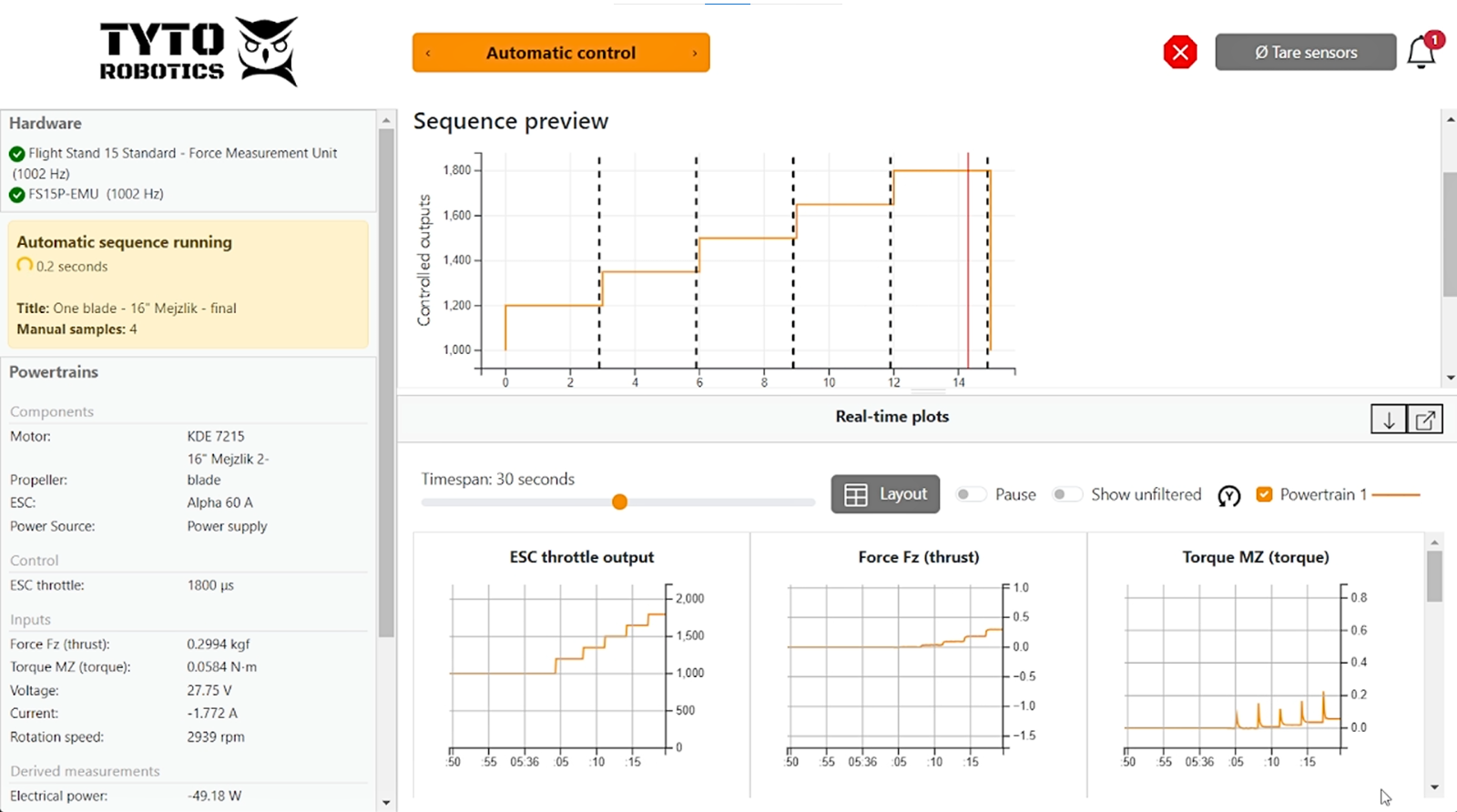

Using the Flight Stand software, we designed and ran an automated step test with five throttle steps:

- 1200µs

- 1350µs

- 1500µs

- 1650µs

- 1800 µs

Below is a screenshot of the software GUI just after the completion of the first test.

Figure 6: automated step test in the Flight Stand software

3. Experimental Results: 1-Blade vs. 2-Blade Propellers

RPM and Thrust

At the same throttle input, the RPM achieved was practically identical for the single-blade and two-blade propellers. The greatest difference occurred at 1650 µs, where the RPM readings were 2330 and 2318 respectively, a difference of a mere 12 RPM or 0.5%. This indicates that our ESC controls RPM in a closed loop, as the load was quite different for the two propellers.

At the same RPM, the thrust output of the two-blade propeller was significantly higher than the single-blade propeller. This result is unsurprising as the two-blade propeller has nearly double the lift producing area as the single-blade prop. The difference becomes increasingly pronounced as RPM increases.

Figure 7: thrust vs. rotation speed for single and two-blade propellers

Propeller Efficiency

When we plot propeller efficiency, which is calculated by dividing thrust (gf) by mechanical power (W), we can see that at all rotation speeds, the single-blade propeller is more efficient than the two-blade propeller. This agrees with the theory discussed in the first section.

Figure 8: single-blade and two-blade propeller efficiency vs. RPM

However, when we plot propeller efficiency against thrust, with the intent of comparing conditions with equivalent flight benefits, we see that the single-blade propeller only maintains superior efficiency at lower thrust.

Figure 9: single-blade and two-blade propeller efficiency vs. thrust

Overall Powertrain Efficiency

Looking at overall powertrain efficiency, calculated as thrust output (gf) divided by electrical power input (W), we observe that the two-blade system is more efficient at all rotation speeds. Both systems increase in efficiency as RPM increases, with a plateau taking shape after about 2500 RPM.

The maximum absolute difference occurred at 1500 µs and 1720 RPM, with the two-blade propeller achieving an overall powertrain efficiency 1.89 gf/W higher than the single-blade system. The maximum difference in terms of percentage occurred at 1200 µs and 495 RPM, where the two-blade propeller was 65% more efficient.

Figure 10: powertrain efficiency vs. RPM for single and two-blade propulsion systems

This is likely observed due to the system’s motor & ESC efficiency, the ratio between mechanical power output and electrical power input. In contrast to the single-blade system’s higher propeller efficiency, the two-blade system demonstrated a much higher motor & ESC efficiency.

The propeller chosen for these experiments was at the small end of propellers suitable for this motor, and the single-blade propeller would have been even less well suited to the motor, as it generated less torque.

The result of operating below the motor’s maximum efficiency zone is that despite the higher propeller efficiency at thrust under 0.175 kgf, the overall powertrain efficiency remains lower for the single-blade propeller for the whole range of thrust and RPM.

In a follow-up experiment, there are several modifications we could make to compare how the propellers perform in ideal conditions. We discuss these points in the next section.

Check out our article on Motor Efficiency Mapping to learn more about measuring your motor’s efficiency.

Discussion: Performance Trade-offs and Confounding Variables

Performance Trade-offs

While it appears that single-blade propellers are indeed more efficient at low thrust values, we must also acknowledge the performance trade-offs that come with using them.

First, in order to achieve balance, the counterweight must be heavier than the original blade that was removed, since the mass is now closer to the hub. The counterweight is essentially dead weight as it does not contribute to lift but likely does contribute to drag (it almost certainly did in our design).

Additionally, one of the major reasons single-blade propellers haven’t been adopted more widely is due to the high levels of vibration they produce. This resounds throughout the system, leading to non-negligible downstream effects like shorter bearing and component lifespans. The consequences of vibration in drones can be severe.

Finally, in this experiment, we investigated the performance difference between single and two-blade propellers in a static condition, but this is not necessarily representative of their performance in-flight. In the future, we could perform the same tests in simulated flight conditions using a Windshaper to get more lifelike results.

Confounding Factors

The experiments completed for this research achieved their goal of allowing us to compare single and two-blade propeller performance. That said, there were a few confounding factors that made the comparison less than perfect.

First, the counterweight on the single-blade propeller was bulky and not very aerodynamic. In an ideal world, we would have manufactured a propeller with a perfectly streamlined counterweight that achieved an ISO balance quality grade of <6.3 G. This would have likely led to even better performance than what we observed.

Next, for mobility and safety reasons, our Flight Stand 15 is mounted on a cart, so tests are carried out with fencing surrounding the propeller. This undoubtedly has an impact on the local dynamics and propeller performance, but we are confident that the impact was fairly consistent from test to test, maintaining the validity of the comparison.

Furthermore, as discussed above, the motor we used for this experiment was likely oversized for the propellers being tested. Since we are measuring torque and mechanical power, this has no effect on the validity of the result. However, if we were designing this for a real drone, we would use the same propellers on a smaller motor (or larger propellers on the same motor) in order to operate in the motor’s peak efficiency zone. This would change the final outcome in terms of overall powertrain performance.

Finally, in this experiment we focused on running the propellers through the exact same test, rather than comparing them at equal performance indicators. It could be interesting to focus on achieving the same thrust with a single and two-blade propeller, either by using different RPMs, or by accepting blades with different shapes and diameters. I.e. testing a single-blade propeller with a diameter twice that of a two-blade propeller, and comparing their power and efficiency at equal thrust.

In a real environment, we also have to consider that the maximum thrust achievable by a single blade propeller is more limited than for a two blade propeller. We can’t have the propeller tip exceeding the speed of sound without a very large performance penalty.

Summary

In summary, our results support the notion that single-blade propellers are indeed more efficient than same size propellers with more blades. That said, the efficiency gain comes with performance trade-offs in terms of reduced thrust output, increased mass, higher vibration, and faster degradation of components.

We appreciate you taking the time to read this article and we hope it has been informative.If you have any questions or recommendations for future tests, let us know in the comments below.

Want more propeller testing content? Download our free white paper on propeller balancing techniques:

Back to Blog

Back to Blog

David Bloomfield

June 26, 2025

Would love to see a comparison between a single blade and two blade with the same loading characteristics. I.e. unequal blade size.