1. Applicable products

- RCbenchmark Series 1520 Thrust Stand

- RCbenchmark Series 1580 Thrust Stand and Dynamometer

- RCbenchmark Series 1585 Thrust Stand and Dynamometer

- RCbenchmark Series 1780 Thrust Stand and Dynamometer

2. What describes your problem?

Please find within the following table which describes your problem. Once selected, mark down the troubleshooting points to follow.

3. Problem specific troubleshooting

3.1 What efficiencies can the thrust stand calculate?

With the RCbenchmark Series 1520, you can obtain:

- Propeller overall efficiency

With the RCbenchmark Series 1580/1585 and Series 1780, you can obtain:

- Motor efficiency

- Overall efficiency

- Propeller mechanical efficiency

With the RCbenchmark Series 1780 coaxial, you can obtain an extra:

- Coaxial dual-propeller overall efficiency

3.2 What is motor efficiency?

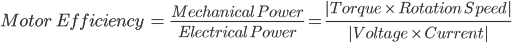

The motor efficiency is calculated and derived:

The thrust stand measures the torque generated by the motor on the load measurement unit and the rotation speed by the optical RPM probe. Voltage and current are the input DC power into the ESC. The motor efficiency is dimensionless.

The motor efficiency is an important factor:

- To determine whether the motor and the ESC are working well together

- To calculate the flight time and the overall flight performance

Generally, the motor efficiency (%) will increase when increasing the speed, until it starts to go down.

Please take note that the motor efficiency is the combined efficiency of the motor and the ESC. The electrical power is the power consumed by the ESC and the motor.

At this stage, we do not have any product that can measure the AC output (voltage and current) from the ESC to the motor.

3.3 What is the propeller’s mechanical efficiency?

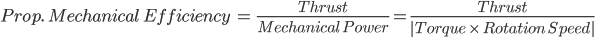

The propeller’s mechanical efficiency is calculated as:

The thrust stand measures the thrust and torque generated by the motor on the load measurement unit and the rotation speed by the optical RPM probe. The propeller’s mechanical efficiency has the unit of measurement of kgf / W (kilogram-force per Watt).

The propeller’s mechanical efficiency is a factor:

- To determine the propeller’s performance

- To determine if the propeller works well with the motor

- To optimize the weight, the shape and the dimension of the propeller

Generally, the propeller’s mechanical efficiency (kgf / W) decreases when speeding up.

For the same propeller tested statically, the thrust is only dependent on the rotation speed (and the geometry around the test area).

3.4 What is the overall efficiency?

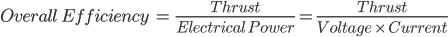

The overall efficiency is calculated:

The thrust stand measures the thrust generated by the propeller on the load measurement unit and the voltage and current at the ESC input. The overall efficiency has the unit of measurement kgf / W (kilogram-force per Watt).

The overall efficiency is a factor:

- To determine if the propeller works well with the whole power chain

- To calculate the overall flight performance

- To determine if the propulsion system is efficient to your vehicle

Generally, the overall efficiency (kgf / W) decreases when speeding up.

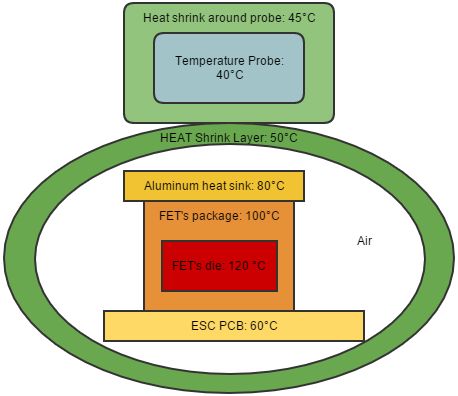

At times, you may observe the overall efficiency further decreases when holding the same throttle. This may be due to the motor starting with cold coils. The electronics’ efficiency goes down with temperature.

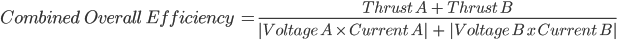

3.5 How to interpret the efficiencies when testing coaxial?

For any coaxial or dual-motor propulsion systems, we can use the overall efficiency of the whole propulsion system to determine the global performance:

The thrust stand measures the two thrusts generated by the propeller A & B on each load measurement unit and the voltage and current A & B of the power chain on the power and control console A & B. The overall efficiency has the unit of measurement kgf / W (kilogram-force per Watt).

The equation above assumes that the dual-motor system uses a sole power source which generates the same voltage for both motors and ESCs. If you are using different power sources for different motors, you may have two electrical power combined.

If you are using the continuous recording or the automatic script control from the software, the output CSV file contains the Thrust A + B (kgf) and Electrical Power A + B (W) and you may simply add a column to derive the combined overall efficiency.

The combined overall efficiency helps to determine the whole dual-motor propulsion system if it is sufficient and efficient to generate the required combined thrust. Please take note that this efficiency may also related to:

- Axial distance between two propellers

- Radial offset distance between two propellers

- Throttle input of two motors

As the upstream propeller is usually more efficient than the downstream propeller, the combined overall efficiency may differ when the controlled speed of each motor is different. Due to the aerodynamic turbulence and drag effect, you may sometimes observe negative thrust for the downstream when the speed difference is too large. For more details, please refer to SGGCOX guideline for the testing dual-motor.

4. Problems persist?

We support all issues related to the measurement tools itself, and we can provide limited support regarding your test setup and power-train selection. If you need extended support for your specific tests, manufacturing facility or UAV, contact us at sales@tytorobotics.com. We offer extended support contracts including phone and video conferences at affordable rates.

To obtain a solution to your problem faster, please indicate which troubleshooting steps you have already done. Also, include the debug log from the software. If relevant, please also include a screenshot or pictures of the issue.

Back to Blog

Back to Blog