By Lauren Nagel

Introduction

If you are building a drone, RC vehicle, or any machine that uses a brushless DC (BLDC) motor, you have likely encountered the concepts of motor Kv and motor poles. Both of these parameters are useful for characterizing your motor and estimating its performance.

In this article we cover what these metrics mean, how to calculate and measure them, and finally how they are related.

Table of Contents:

- How to Calculate Brushless Motor Kv

- What is motor Kv?

- What does Kv rating mean?

- How to measure calculate Kv (equations)

- How to measure motor Kv

- How to Determine the Number of Poles in a Brushless Motor

- What are motor poles?

- Motor poles vs. pole pairs

- Motor poles and electrical speed

- How to calculate motor poles (equations)

- How to measure motor poles

- The Relationship Between Motor Poles and Kv

After performing the calculations, we will use the Series 1585 thrust stand to confirm our results.

Part 1: How to Calculate Brushless Motor Kv

What is Motor Kv for Brushless Motors?

Motor Kv provides a way to describe the relationship between the peak voltage and rotation speed in a brushless motor in a no-load condition. The unit for Kv is RPM/V and it can be estimated by dividing the rotation speed of the unloaded motor with the applied voltage.

In truth, the voltage we should consider is in fact the back electromotive force (EMF) and not the applied voltage.

In a brushless motor, the back electromotive force (EMF) is a voltage that occurs in the opposite direction of the current provided by the power source, induced by the movement of the coils through the magnetic field in the motor.

This can be explained by Faraday’s law, which shows that a coil moving inside a magnetic field creates a flow of electrons inside the coil, called a voltage or emf.

When the motor turns, the back EMF generated is proportional to the speed of the rotor: as RPM increases, back EMF does as well. At full throttle with no load (ignoring the motor’s own inertia), we can describe the relationship with this formula:

What does the Kv Rating Mean?

The Kv rating provides an estimate of how many rotations a motor will undergo for every volt applied to it. This rating can be helpful for comparing motors that are of the same size physically, but have different performance characteristics due to their inner workings.

As a general rule, as the number of windings in the coils increases, the Kv of the motor decreases. Mechanically speaking, low Kv motors have a higher number of windings of a thinner wire and the thin wire carries more volts at lower current.

High Kv motors have fewer windings but a thicker wire that can carry higher current with fewer volts. The equations in the next section provide a mathematical demonstration of this concept.

Further reading: BLDC Motor Power and Efficiency Analysis

Applied to drones, low Kv motors tend to operate at lower RPMs and produce more torque, ideal for larger propellers and large drones. High Kv motors operate at higher RPMs and are ideal for low torque, small, and fast spinning propellers.

Therefore, lighter, fast moving drones such as racing quads are best served by high Kv motors and heavier, slower moving drones are better served by low Kv motors.

Figure 1: The EMAX Hawk Pro racing drone uses a 2400 Kv motor whereas the Foxtech Gaia 190MP heavy lift drone uses a 100 Kv motor

Another practical application is for inrunner and outrunner motors. An inrunner typically has a higher Kv value than an outrunner of the same size. The larger diameter of the rotor in the outrunner allows for more permanent magnets.

More magnets (poles) → lower speed → lower Kv. The small diameter of the inrunner also means it has a smaller circumference to cover for one rotation, thus more rotations for the same voltage.

It’s important to note that Kv is not a definitive way to evaluate a motor’s performance as the brand of motor can also affect its efficiency. For the same Kv value, a motor from one brand may perform better or worse than another, which will only be revealed through testing.

How to Calculate Motor Kv

If we go back to our earlier formula:

We can rearrange it to show that:

To approximate Kv, you can swap ‘Back EMF’ with input voltage in the equation, which will give you a pretty good estimate of motor Kv.

For a more accurate estimation, you can measure the voltage between two leads in the circuit to obtain your root mean squared (RMS) voltage, then multiply it bysqrt(2) or 1.414 to obtain peak voltage, which you can plug into this equation:

0.95 is a value that accounts for deviations from the theoretical model to provide a value closer to that which is experimentally observed. This factor is commonly accepted for Kv calculations.

How to Measure BLDC Kv

Measuring Kv experimentally is perhaps the best way to get an accurate idea of your motor’s true Kv. We have regularly observed differences between the stated and measured Kv of the motors we’ve tested, which you will likely observe as well.

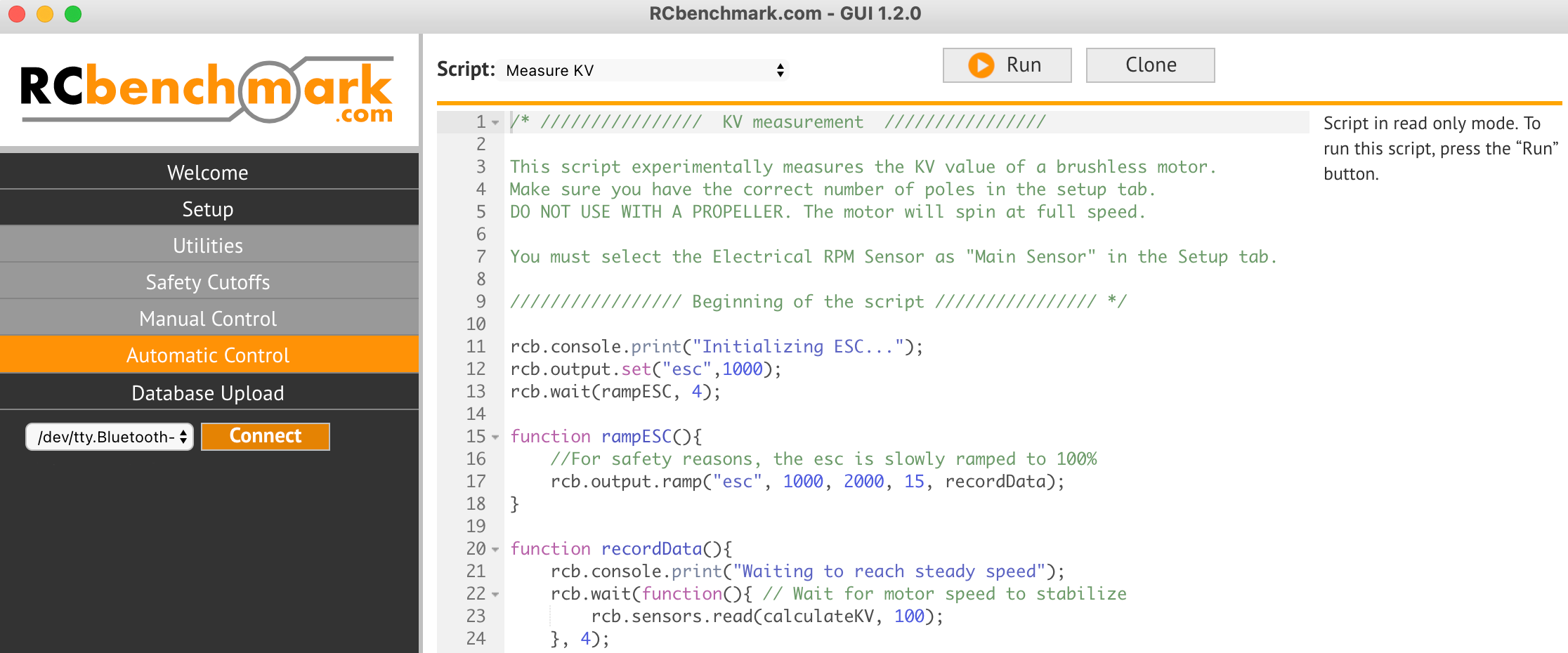

We provide a pre-written script in our RCbenchmark software that allows you to measure Kv experimentally by running your motor through a no-load test.

All you have to do is hook up your motor to an RCbenchmark test stand, input the number of motor poles in the Setup tab, then run the test (without a propeller). The software will calculate your motor’s Kv automatically once the test is finished.

Even if your motor is labelled with a Kv rating, it can be interesting to test it to see if the experimental Kv matches what is advertised.

Figure 2: The automatic script that calculates Kv using the RCbenchmark software

Part 2: How to Determine the Number of Poles in a Brushless Motor

What are Motor Poles?

Within a brushless motor, there are a number of magnets lining the circumference of the rotor (figure 1). These magnets are also referred to as the ‘poles’ of the motor. When an electric current is delivered to the coils in the stator, the rotor starts to turn as its magnets repel the like electromagnets.

In the diagram below, the blue rotor contains the permanent magnets in an inrunner motor (left) and an outrunner motor (right). The green stator holds the electromagnetic coils.

Figure 3: Motor magnets / poles in inrunner and outrunner motors

Motor Poles vs. Pole Pairs

The magnets lining the rotor each have their own north and south end, with just one of those ends facing and interacting with the stator. There are an equal number of north and south magnets facing out from the rotor, and each set of N and S magnets is referred to as a ‘pole pair’.

For each pole pair in the motor there are two poles, so if the motor has 8 poles / magnets, there are 4 pole pairs. For this same reason, you will almost always have an even pole number (2, 4, 6, 8, etc.), as each magnet needs an opposite pole.

Ex.

- 2 pole motor → 1 north magnet and 1 south magnet → 1 pole pair

- 8 pole motor → 4 north magnets and 4 south magnets → 4 pole pairs

Relationship Between Motor Poles and Motor Electrical Speed

The speed of the motor is inversely related to the number of poles in the rotor. The relationship is explained by the following formula:

Where:

Ns = synchronous speed

f = frequency of three-phase power supply

And #p = the number of poles

Alternatively, it can be written as:

Where:

Ns = synchronous speed

f = frequency of three-phase power supply

And #pp = the number of pole pairs

How to Calculate Motor Poles

Since the number of poles is equal to the number of permanent magnets in the rotor, the simplest way to determine the number of poles is to count the magnets manually.

This is possible if you can see into your motor or if you are able to remove the outer casing. If you are unable to remove the casing this can be a challenging task as the magnets can be quite small and numerous.

Further Reading: How BLDC Motors Work

Figure 4: Counting the magnets / poles inside a brushless motor

Other simple procedures have been suggested, like waving a magnet around your rotor to see where attraction and repulsion occurs. This method is most feasible for outrunner motors where the magnets are outside the stator near the surface.

Be careful if you attempt this technique as the magnets inside your rotor can be demagnetized by the influence of a stronger magnet.

Another option that requires a bit more effort and equipment involves finding the motor speed and power supply frequency experimentally, then rearranging the equation below to solve for the # of motor poles:

To measure your motor speed, you will need a piece of equipment to back-drive your motor (a drill, for example), plus a rotation speed-measuring device to measure the number of rotations, such as a tachometer.

You will also need a device to measure the frequency of the back EMF generated, such as an oscilloscope. Measure the speed and frequency simultaneously, then input the values into the equation above to determine the number of poles in your motor.

Measure the Number of Motor Poles

Perhaps the simplest way to measure the number of poles in your motor is to have a test stand determine it for you.

Several of our test stands come with automatic, pre-written scripts for calculating the number of poles in your motor, including the Series 1585.

Simply enter the Kv rating of your motor in the script, then run the automatic test with your motor installed on the test stand (without a propeller, as the motor will run at full speed).

The software will provide you with the pole count for your motor as soon as the test is done, which takes just a couple of minutes.

Figure 5: The automatic script that counts motor poles using the RCbenchmark software

Part 3: The Relationship Between Motor Poles and Kv

As shown in the previous sections, motor Kv and the number of poles are both related to the speed of the motor / RPM. We know that as rotation speed increases, Kv increases as well. Alternatively, a higher number of poles corresponds to motors that operate at lower RPMs.

The relationship between the number of motor poles and Kv is thus inversely proportional. This makes sense when we think about it practically.

A larger motor with a greater number of poles will require high torque and operate at a low operating speed. The motor used would thus have a high number of poles and a low Kv.

A smaller motor with fewer poles will operate at high RPM and produce relatively low torque. The motor will therefore have a low pole count and a high Kv.

Conclusion

The concepts covered in this article, brushless motor poles and motor Kv, are two concepts that are key for understanding the properties and performance of BLDC motors. Knowing how to interpret these numbers can help you choose the best motor for your drone or electric aircraft and improve your performance and efficiency. Efficiency is directly related to flight time, payload and range, so this information is very valuable.

If you would like to be able to measure the number of poles in your motor and your motor’s Kv automatically, we suggest checking out our motor testing tools:

- Series 1585 - measures up to 5 kgf of thrust / 2 Nm of torque

- Flight Stand 15 - measures up to 15 kgf of thrust / 8 Nm of torque

- Flight Stand 50 - measures up to 50 kgf of thrust / 30 Nm of torque

- Flight Stand 150 - measures up to 150 kgf of thrust / 150 Nm of torque

If you have any questions about the contents of this article, don’t hesitate to leave us a comment and we will be sure to respond.

Further reading: How to Test a Brushless Motor with a Thrust Stand

Back to Blog

Back to Blog

Teddy

March 25, 2024

Apakah ada rumus atau trik tertentu untuk menentukan jumlah pemasangan magnet pada pembuatan motor brushless karena sy tidak memiliki semua alat yg di sebutkan di artikel.dan jika menggunakan rumus bisakah di sertakan contoh soalnya.terimakasih