3D printing of UAV rotors is possible, but can the noise and aerodynamic performance be similar to that of commercially available plastic rotors?

To address this question, the Nederlands Lucht- en Ruimtevaartcentrum Living Lab funded a project aimed at comparing the performance of 3D-printed propellers with that of commercially available propellers.

The Series 1585 thrust stand was used to characterize rotor performance, including thrust, torque, RPM, power, and efficiency.

The reference plastic propeller was 3D scanned and printed with PLA material and an FDM 3D printer. The research team also made some attempts with fiber reinforced printing, but the lines were thicker and resulted in a poor quality trailing edge, affecting performance and noise.

Before smoothing the surface of the 3D printed propeller, a simple performance test was performed (no acoustics were measured). The surface roughness had a notable effect on the thrust, which was in line with expectations for the low-Reynolds number blades.

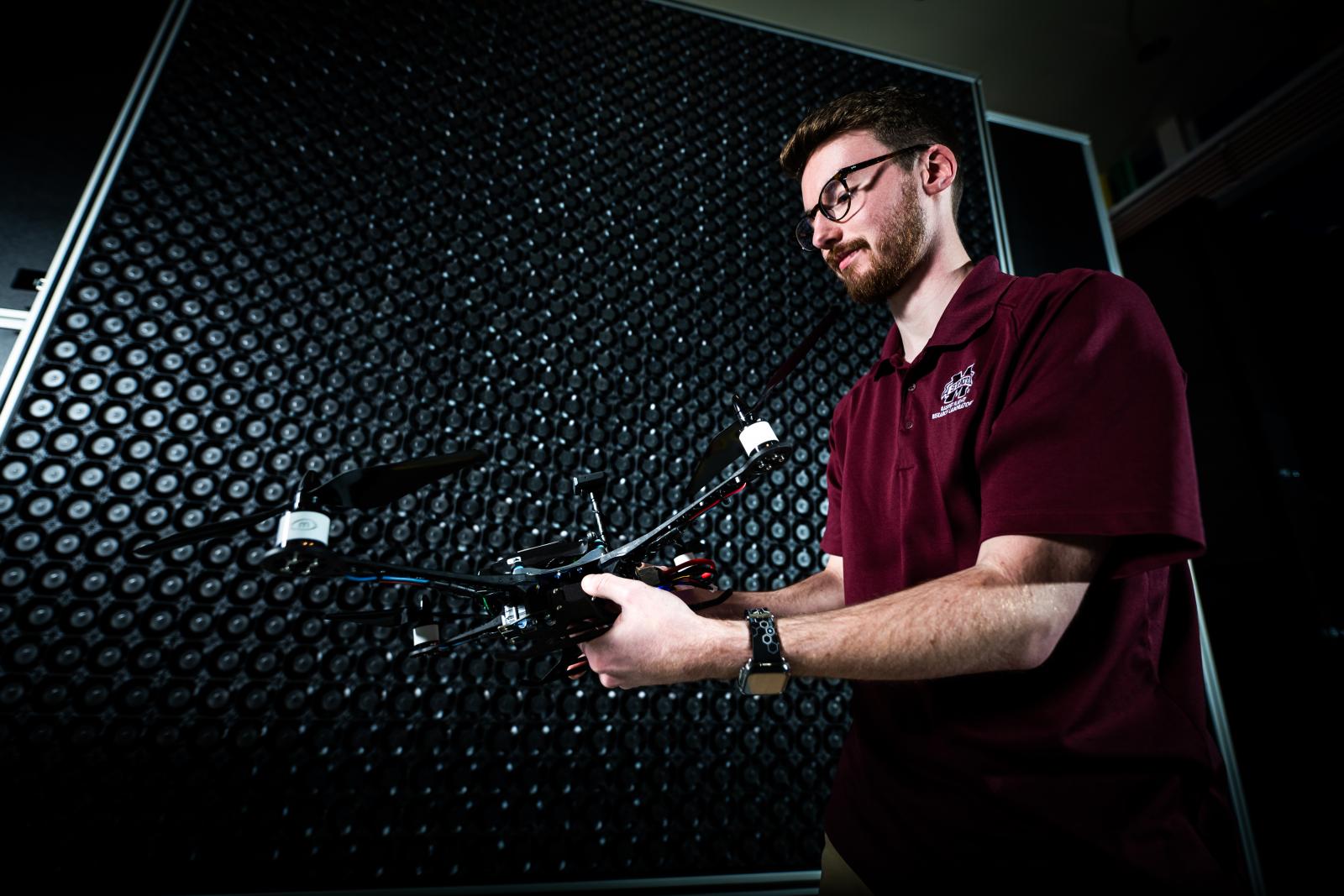

After smoothing the rotor's surface, both the original and 3D-printed rotor were tested in the anechoic room at NLR’s Aeroacoustic Wind Tunnel.

A comparison of the results shows that both rotors have a similar aerodynamic and aero-acoustic performance. This suggests that 3D printed propellers can be useful in the validation and experimentation of complex rotor blade designs aimed at reducing noise in small UAVs.

Back to Blog

Back to Blog

Leave a comment